Description

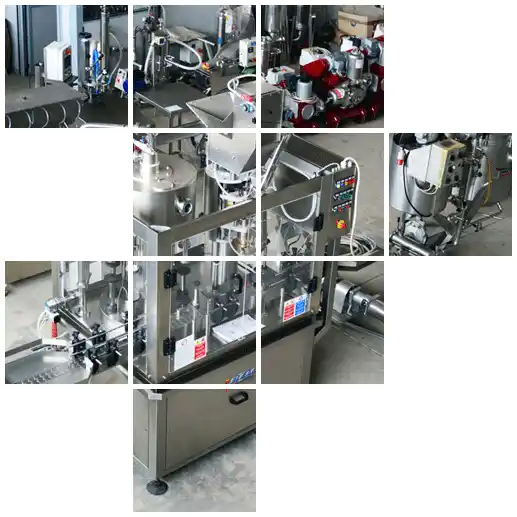

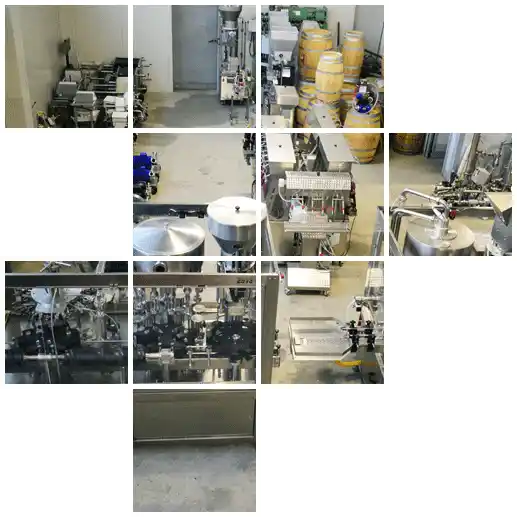

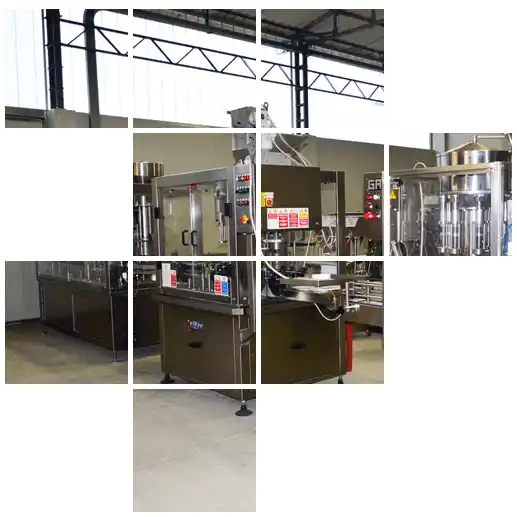

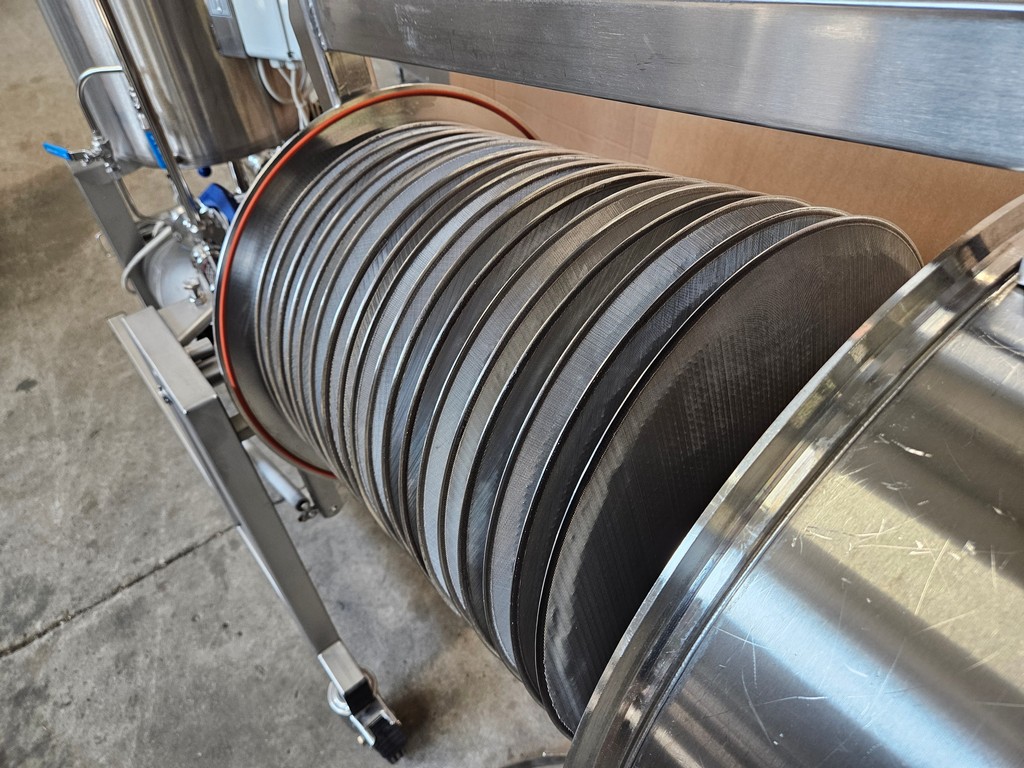

Kieselgur filter Spadoni in stainless steel, 3mq of filtering surface, model DCBL 80, year 2010, horizontal sheets, with centrifugal feeding pump, distributing/mixing pump for Kieselguhr dose, butterfly piping.

Oscillating movement for horizontal sheets cleaning.

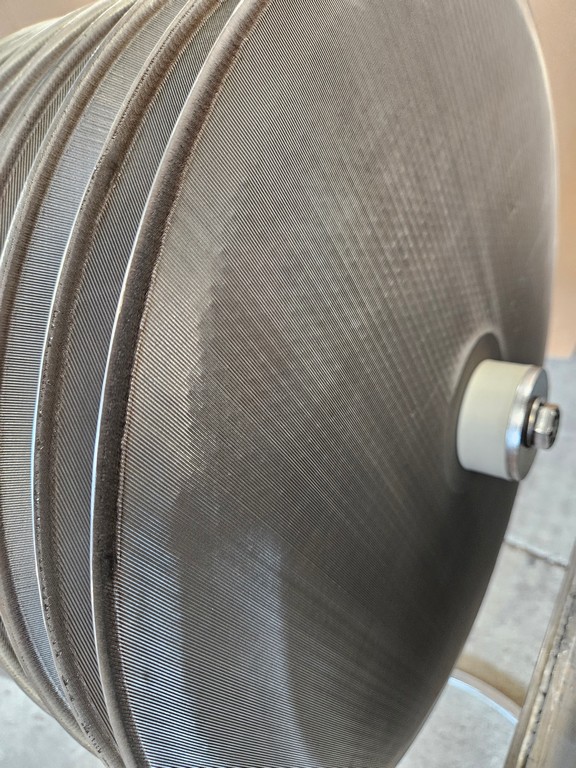

Last disc for residual filtration in the bell.

Dimensions: Length 1400mm x Width 800mm x Height 1600mm about.

Weight Kg 240 about.

Aisi 304 stainless steel mobile device built entirely, stainless steel Reps fabric filter discs, stainless steel electric pump – stainless steel pipes and valves, diaphragm pump for dosing the diatomaceous earth, recovery of the residual liquid by means of the last filter disc, quick cleaning of the filter pack and without dismantling the pipes.

TECHNICAL DESCRIPTION

The extremely sturdy frame is built in Aisi 304 steel mounted on wheels, 2 of which are equipped with brakes.

It supports:

1. FILTRATION SECTION

– Filter chamber

– Stainless steel central collector

– Induction welded Reps fabric disc filter elements on the circumferences

2. KIESELGUR DOSING SECTION

– Stainless steel tank for the introduction of dry diatomaceous earth.

– Piston type dosing pump, such as to allow the constant, regular and continuous addition

of the diatomaceous earth to the incoming liquid stream for the entire duration of the filtration, pump

suitable for shaking the diatomaceous earth in the large tank.

3. PUMP SECTION

– AISI 304 stainless steel feeding pump with mechanical seal with combined electric motor.

– Set of pipes complete with AISI 304 stainless steel butterfly valves with inlet, outlet and taps for self-emptying and sampling.

– Group for venting the filter air.

4. RESIDUE FILTRATION SECTION

The machine is equipped with a system for recovering the residual liquid using the last disc with the

aid of the same feed pump or with gas.

5. RESIDUE DISCHARGE SECTION (CLEANING)

To clean the filter, simply remove the lid closed with clamp and thanks to the patented tilting system, the filter pack is cleaned quickly and effortlessly with minimal water consumption thanks to the shock absorber for the rotation of the bell that slides easily on a special rod.

6. ELECTRICAL AND CONTROL EQUIPMENT

– Electrical equipment compliant with safety standards.

– Pressure control gauge at the inlet.

– Built-in flow meter graduated in Hl/h.

– LED control lights at the turbid inlet and at the filtrate outlet.

Model DCBL 80

Surface area 3 m2

Production Hl/h 80

Power supply Kw 2.44

Dosing capacity Lt 70

Length mm 1,400

Width mm 800

Height mm 1,600

Weight Kg. 240

Voltage 380 50Hz 3ph

Connections 40 clamp

The equipment is in a excellent conditions, like new.