Description

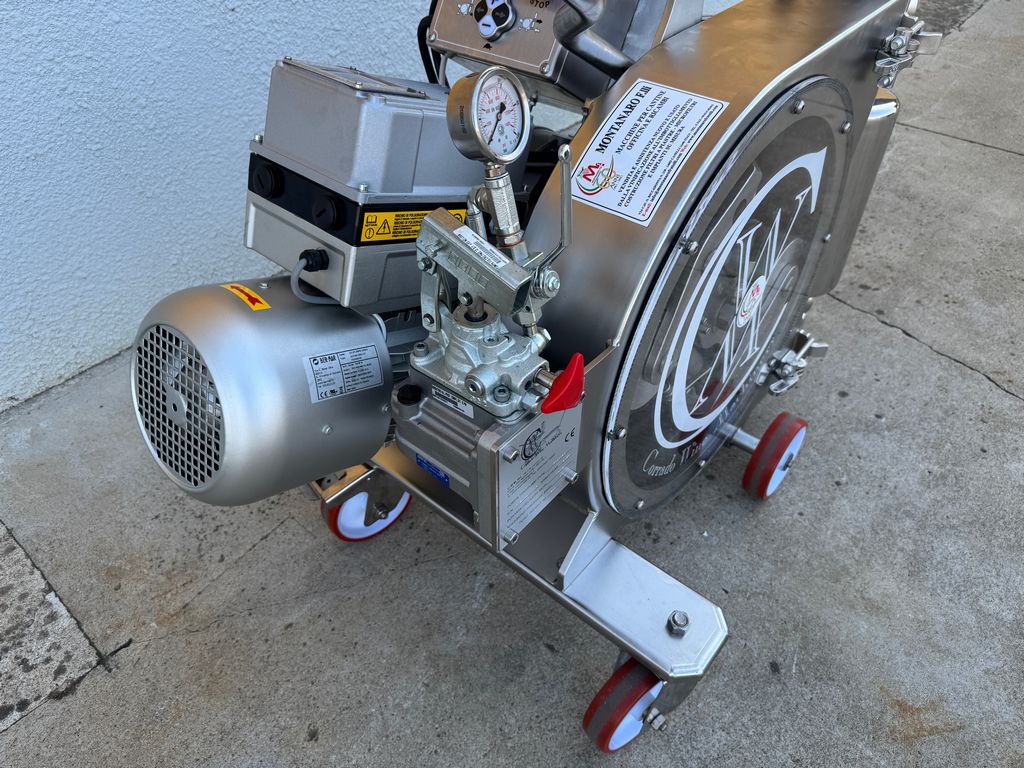

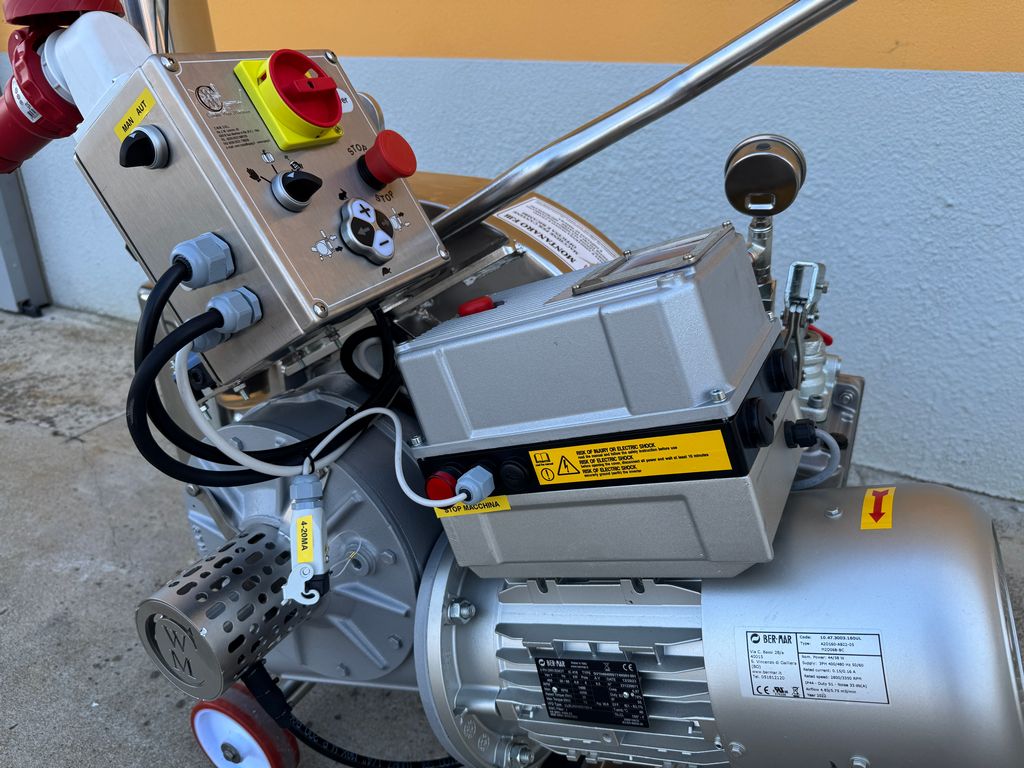

Peristaltic pump type PRST 120, entirely manufactured in AISI 304 stainless steel, with parts in contact with the liquid made of AISI 316, suitable for the transfer of liquids even with high density and in the presence of solid particles.

Motor power: 4 kW.

Hourly flow rate: 0–120 hl/h (liquid).

Pump speed: 0–70 rpm.

Maximum working pressure: 6 bar.

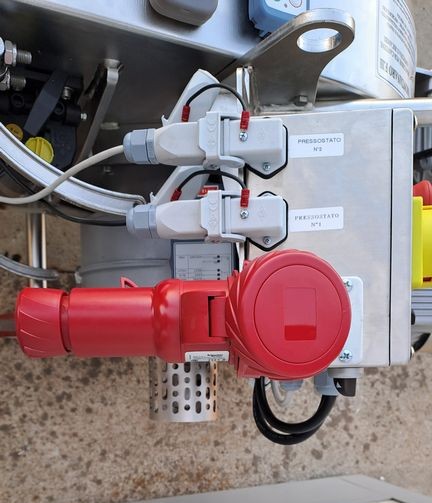

Pressure switches and flow indicator.

Dimensions: 1180 mm x 680 mm x 980 mm about.

Maximum operating pressure: 6 bar (on request 15 bar).

Variable flow rate (PRST 120 from 0 to 12,000 l/h with liquid).

Motorization by latest-generation inverter with anti-interference filters, constant torque and auxiliary forced ventilation.

4 kW for PRST 120; 7.5 kW for PRST 260.

Reversible pumping.

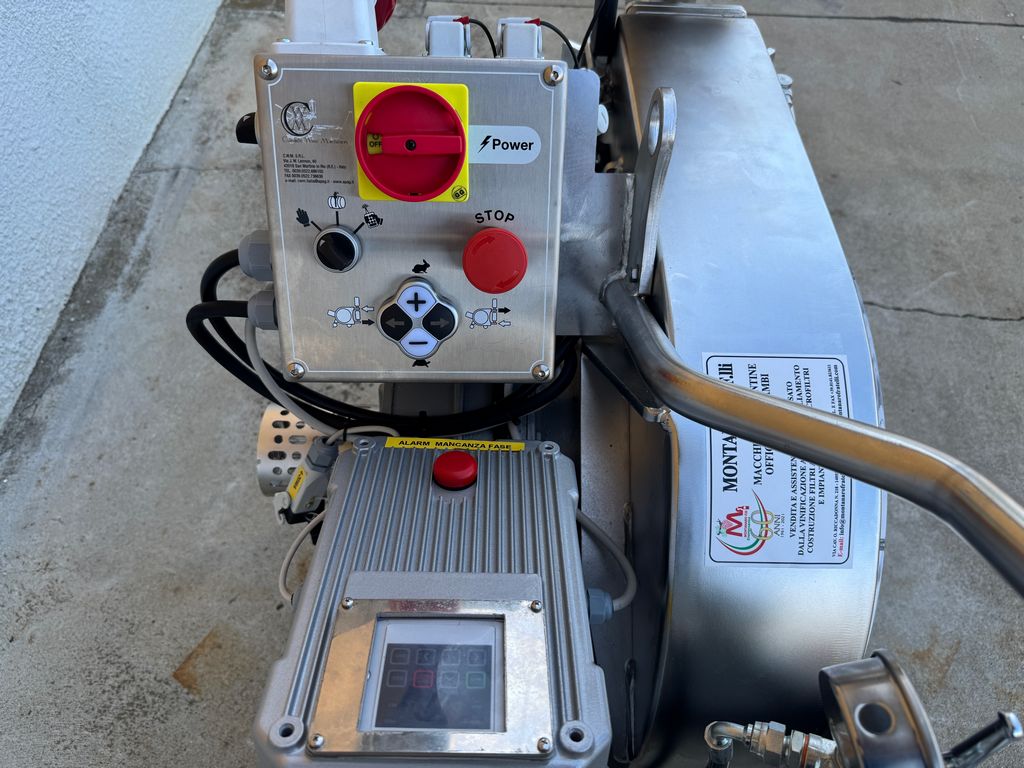

Electrical control panel in AISI 316, compliant with CE standards, complete with:

main switch, thermal relay, speed adjustment potentiometer, rotation direction selector, minimum voltage relay, pumping pressure control via stainless steel glycerin-filled pressure gauge and pressure switch active in both pumping directions.

Possibility of applying remote control via radio, cable and level probes.

Continuous flow rate visualization via high-efficiency display (non-programmable liter counter).

Machine entirely manufactured in stainless steel, including parts not in direct contact with the pumped fluid, with minimum thickness of 12 mm.

Tube lubrication by means of an external pump capable of gradually releasing lubricant without removing the cover.

Indirect compression of the pumping tube, thanks to a patented rocker system, which also ensures the absorption of impacts caused by the accidental entry of solid bodies such as stones or pieces of wood.

Bidirectional internal by-pass, without product recirculation, adaptable to the requirements of the pumped fluid for flow rate and operating pressure modulation; this system avoids the application of costly and bulky external by-passes.

Automatic roller lifting system to prevent tube compression when the pump is stopped, increasing tube service life; this system allows complete pump cleaning with CIP cycles, ensuring total sanitization.