Description

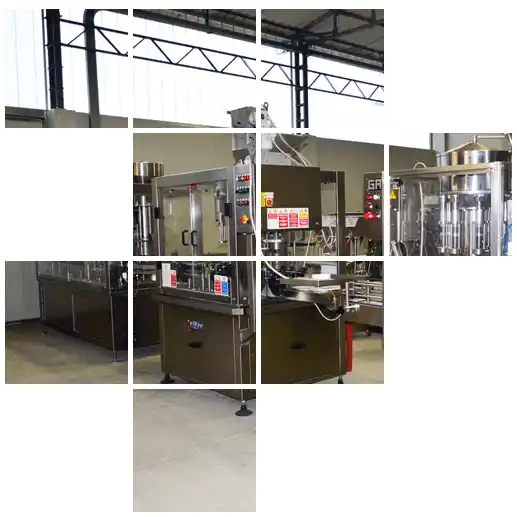

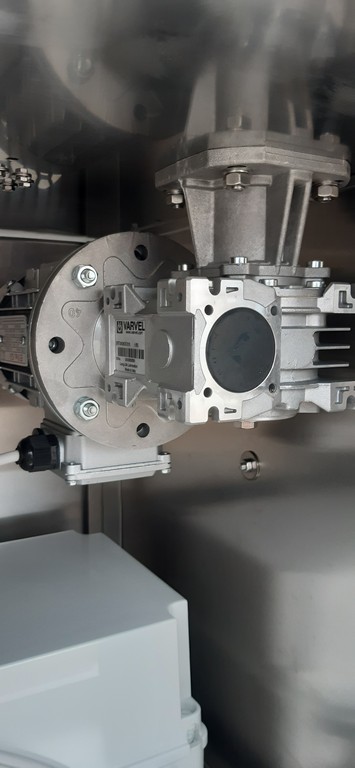

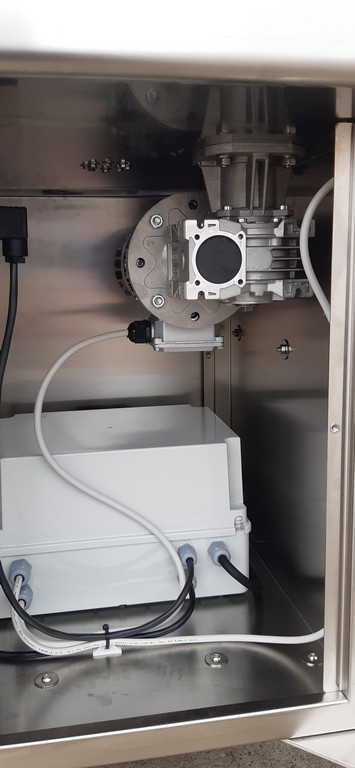

Stainless steel semiautomatic rinser machine, model “TP10”, is mounted on wheels, it is manufactured in stainless steel and plastic components in conformity with the international directives. It is designed to rinse new bottles, to clean the inside from powder and any small particle, prior to the filling operation. The operator places by hand the bottle upside down in one of the 10 positions on the central plate of the machine. The plate is turning with step-by-step motion. One rinsing nozzle is spraying the water inside the bottle, then the table goes on rotating so that the water is dripping down together with any part to be removed. The water jet is operated by the bottle itself (no bottle – no spraying). The water is dripping out for all the time needed for the bottle to make a complete turn, before the operator can take it away. The rinser is supplied including a filtering assembly for the water, including a micro-filtration cartridge of 0,45 µm. The working speed of the machine is set to achieve a constant output of 700 bottles per hour.

Technical data:

- Bottles: Standard from 37,5 cl to 5 lt – Glass and PET, special versions available on demand

- Dimensions: 670mm x 670mm x Height 750 mm

- Noise level: Lpa < 30 db (tests according to UNI 7712)

- Base-frame: Stainless steel AISI 304 quality

- Bottles loading-unloading: Manual Operation Automatic

- Installed Power: 0,18 Kw

- Water consumption: 30-40 lt/h

- Weight: 64 Kg

- Standard voltage: 220V – singlephase – 50Hz